Wastewater and Agricultural Waste Management

James Elliot

402G Solutions Inc. Advisor

For turn-key services that offer clean technology solutions for territory-appropriate and sustainable waste management in wastewater treatment facilities (WTF) and agricultural wastes (dairy, swine, etc.), there are worldwide efforts to integrate technologies together to provide optimized solutions. The challenge for any country / governing body to select the most effective solution that is appropriate and sustainable is to filter solution offerings with domain experts linked to financing organizations to realize solutions in a timely matter.

Of course, to cover this topic in a Blog series is a substantial challenge and I will attempt to summarize different critical components in this and upcoming blogs. Important in the discussion is the perspective that wastewater and agricultural to be treated as an important resource / feedstock to be converted to reusable, recyclable and recoverable water and nutrients. For centuries wastewater treatment facilities and agricultural waste management practices have strived to use waste as a resource. To continually improve processes and optimize this resource utilization is a worldwide necessity and can be both prosperous and evidence of societies commitment to posterity.

INDUSTRY BACKGROUND

Municipalities worldwide strive to urgently to produce higher-quality treated effluent, reduce waste residuals for disposal, and implement resource recovery in the most sustainable manner. Wastewater treatment facilities (WWFs), regardless of size, will require investments in upgrading and/or expanding their treatment facilities, to meet a worldwide demand for environmental regulations. There is increasing pressure to ban (or at best reduce) the use of municipal bio-solids as fertilizer in developed countries, and an anticipated requirement for WWFs to reduce their carbon footprint and become energy neutral, after the Paris Climate Summit (The 2015 United Nations Climate Change Conference, held in Paris, France, from 30 November to 12 December 2015). In addition, over 50% of the annual operation and maintenance costs are attributed to sludge handling, treatment and disposal for most WWFs. Conventional anaerobic digesters for mixed sludge treatment operate at very long hydraulic retention times (25 days and up), resulting in inherent high capital cost. Also, with expanding population, existing digesters in many WWFs will not be able to handle the additional sludge loads; adding new digesters (assuming land is available on-site) will require significant additional capital investment. Adopting MW-AOP technology into any existing plant, will transform a conventional system towards a “zero sludge” (or a very low sludge yield) wastewater treatment system, with several co-benefits.

STAKEHOLDERS

The wastewater treatment industry is comprised of WWFs that carry out the task of treating a territory’s wastewater. The WWFs are most typically publicly owned facilities, but in some cases, they can be privately owned. Plants are typically designed for an expected population growth for 15-25 years. Major design and process upgrades are made within 5-8 years of their design life (40-50 years). WWFs look for a payback of 10 to 15 years for upgrades. Minor changes in process are carried out between the major upgrades to address significant performance problems, or to take advantage of expected short term cost savings.

ENERGY-BASED APPLICATIONS

One of the principal components of a turn-key solution addresses the most efficient and cost-effective energy-based applications. Thus, in reviewing energy-based solutions, it is important to consider the contribution that the commercialization of industrial microwave-based technologies has made over the years. For example, this blog discussion will focus work done to realize the commercialization of the microwave enhanced Advanced Oxidation Process (MW-AOP). It is important to reference a patent describing this process Method and Apparatus Using Hydrogen Peroxide and Microwave System for Slurries Treatment in patent application serial no. US patent 8444861; CA 2660181, published in May 2013. The University of British Columbia patent for the MW-AOP system can be found at: http://www.google.ca/patents/US8444861. As critical component of the MW-AOP system is the microwave unit, a quick review of improvements in microwave technologies is prudent. To understand the progress, there is value in acknowledging some important developments that laid the technical foundation for improvements to the dielectric heating process in the microwave unit. From1950s through 1980s generators that were invented to deliver frequencies capable of realizing microwave ablation benefited from:

- critical radar parts inventions; and

- industrial manufacturing innovations & improvements.

Microwave frequencies for ablation applications were largely restricted to Industrial , Scientific, Medical (ISM) bands and in particular 915 MHz and 2.45 GHz. Throughout those 4 decades, microwave applicators were restricted in improvements to: waveguides; crossing profiles of co-axial tubing; materials of use; and a lack of sophisticated simulation software. Fortunately, for the wastewater and agricultural waste industry, the ongoing improvements to the performance of microwave systems has positively impacted significant industrial application benefit.

The development of the MW-AOP technology was supported by the British Columbia government innovation efforts to address: nutrient management problems; and better manure solids reduction prior to land application. Why is this important:

- There is serious pollution worldwide;

- There is a desire for “zero sludge” technology;

- There is a potential phosphorous shortage;

- There is a worldwide unmet need for appropriate and sustainable waste management.

BENEFITS

Some benefits of the MW-AOP technology can be summarized as:

- Clean-tech waste management;

- Enhanced nutrient and energy recovery;

- Organic solids reduction/destruction;

- Pathogen destruction;

- Modular design to accommodate capacity expansion;

- Reduced pollution discharge;

- Reduced Noxious Oxides and Volatile Organic Carbon footprint;

- Economic savings and sustainability;

- Low-cost infrastructure.

As a side comment – The “New Silk Road” initiative commonly referred to as the Belt and Road Initiative (BRI) initiated in China in the early 2010’s was greatly impacted by the global pandemic, however, has recently been rebooted and considered one of China’s key foreign policies whereby BRI is smaller and greener than originally programmed. In addressing environmental concerns while building communications and infrastructure, the features and benefits of MW-AOP technology fits into the mission of this most ambitious BRI.

MW-AOP Technology Description

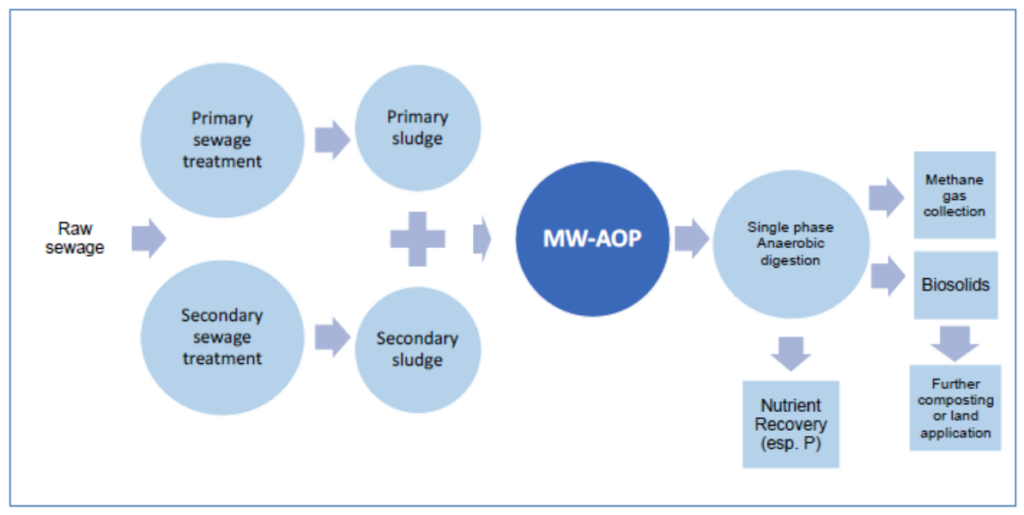

MW-AOP is an organic solids destruction technology that uses microwave heating and a key oxidant, to effectively disintegrate solids, release nutrients for further recovery (as struvite) and provide an ideal feed stream for accelerated anaerobic (no oxygen) digestion and methane production (e.g., municipal sewage sludges, dairy manure, etc.). Collectively, this technology package is being termed Integrated Waste Treatment System (IWTS) and represents a unique approach to organic solids management in the wastewater industry. (See Figure 1).

The MW-AOP operates at significantly lower costs, compared to current state-of-the art, standard marketable technologies. The following key benefits and advantages realized:

(1) A significantly reduced volume of solids (more than 80% waste sludge reduction and in excess of 40% reduction of manure solids) that need to be disposed of further; associated reduced operational and maintenance costs. (30-50%)

(2) Higher rates of methane and subsequent energy production, concurrent with reduced digester hydraulic retention times and a significantly smaller reactor footprint (1/2 to 1/3 of a conventional digester). This will also allow for capital savings on new digesters or future upgrades. Significant greenhouse gas credit can also be achieved.

(3) Enhanced sustainability of municipal wastewater and animal farming industries (e.g., daily and swine wastes) and commercial organic based industries (e.g., food processing).

As demonstrated in the field studies, the MW-AOP has proven beneficial to livestock farmers (especially feed lot-based practices) to develop more sustainable, manure management practices (in excess of 40% reduction of manure solids), while simultaneously generating valuable by products, such as biogas and fertilizer pellets.

MW-AOP Results

- Solids reduction (“Zero Sludge”) – resulting in significant reduction of disposal costs by 40-60%

- Volatile fatty acids conversion – resulting in more efficient biogas production;

- Nutrient release – resulting in nutrient recovery (e.g. struvite = a slow-release fertilizer

- Disinfection – resulting in safe reuse and recycle.

For those fellow schematic-interested individuals: An integrated organic slurry treatment system:

The appropriate and sustainable wastewater management system includes:

- MW-AOP

- Struvite crystallizer

- Advanced anaerobic digesters

OVERALL BENEFITS:

- Much less nutrient discharge into water bodies / holding ponds;

- Significantly reduced sludge handling costs

- Efficient struvite recovery providing: balanced nutrient management; and commercial revenue potential;

- Elevated rate of bio-energy production with much smaller reactor volumes and increased Bio-energy revenue

SPECIFIC EXAMPLE – Dairy Industry:

For dairy farms of all sizes, land application of manure is an important part of the waste management scheme. Nutrients contained in the manure usually exceed the amounts required by the crops grown, resulting in excessive nutrient build-up in soil and causing surface water and ground water contamination.

To achieve a sustainable operation, a portion of the excess nutrients needs to be recovered and removed from the farm site or additional crop land secured, for manure spreading. The MW-AOP can be vital to the nutrient management scheme for high-density, intensively operated dairy farms that are on a limited land base.

The benefits to the Dairy Industry include:

1) Making small farm, anaerobic digesters (AD) economically viable;

2) Reduction of manure solids volume by 40-50%;

3) Enhance bio-methane production by 30%;

4) Hydraulic retention time reduced to less than 8 days AD’s;

5) Increased capacity of AD up to 40-50%;

6) Significant Bio-methane production from liquid manure alone;

7) Ability to improve co-digestion of 3rd party source separated organics and fat, oil and grease;

8) Excess Phosphorus diverted from land application;

9) Potential to produce valuable fertilizer (e.g. struvite);

10) Reduced noxious oxides and volatile organic carbon footprint from dairy manure management

Works Cited and Consulted

Much of these discussions should be attributed to Professor Victor Lo as most of the narrative is taken from his presentations and lectures (Dr. Victor Lo, Professor at the Civil Engineering Department at the University of British Columbia). Future blogs will expand in more detail the topics discussed within and, of course, answer and questions/comments from readers.